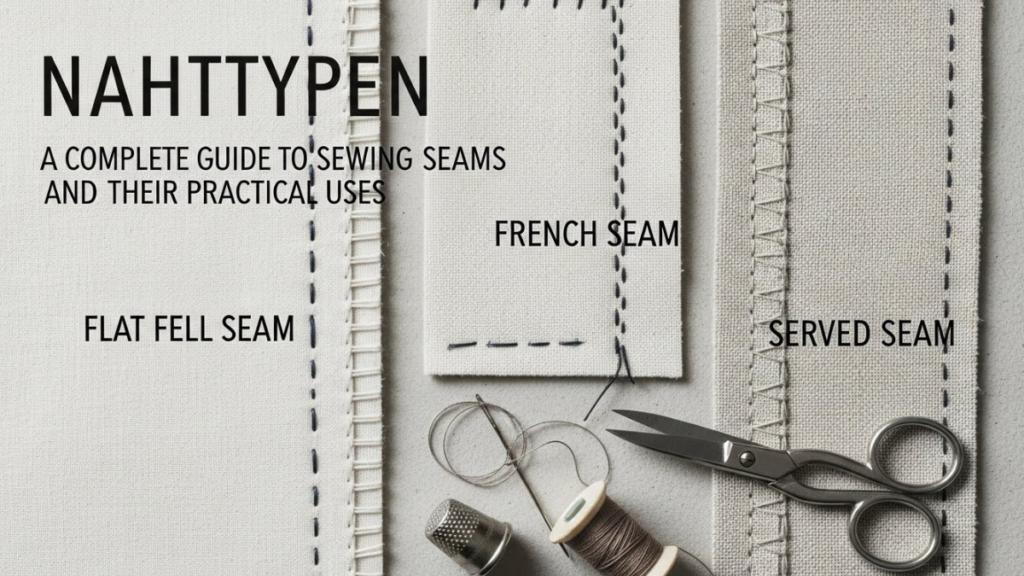

Nahttypen play a crucial role in sewing, tailoring, and textile manufacturing, as they define how different fabric pieces are joined together. Whether you are a beginner learning basic stitching or a professional working in garment production, understanding nahttypen helps improve durability, appearance, and comfort in finished products. From everyday clothing to industrial textiles, the right seam type ensures strength, flexibility, and aesthetic appeal.

This detailed guide explores the most common nahttypen, their characteristics, applications, and advantages, helping readers make informed choices for various sewing projects.

What Are Nahttypen and Why Are They Important?

Nahttypen refer to the different types of seams used to join fabrics together. Each seam type is designed to serve a specific function, such as reinforcing stress areas, preventing fraying, or creating a decorative finish. Choosing the correct seam can significantly impact the longevity and quality of a garment.

In fashion design and textile production, nahttypen influence not only structure but also comfort and style. A poorly chosen seam may cause discomfort, fabric damage, or early wear, while a well-selected seam enhances both functionality and visual appeal.

Basic Nahttypen Used in Sewing

Understanding basic nahttypen is essential for anyone working with fabric. These seams form the foundation of most sewing projects.

Plain Seam as a Classic Nahttypen Example

The plain seam is one of the most widely used nahttypen. It involves placing two fabric pieces right sides together and stitching along the edge. This seam is easy to construct and suitable for lightweight to medium-weight fabrics.

Plain seams are commonly used in shirts, dresses, and simple household textiles. While they are versatile, they may require finishing techniques like zigzag stitching or pinking to prevent fraying.

French Seam in Modern Nahttypen

French seams are elegant nahttypen often used for sheer or delicate fabrics. This seam encloses raw edges within the stitching, creating a clean and polished interior finish.

Commonly found in blouses, lingerie, and baby clothing, French seams provide comfort and durability while maintaining a refined appearance. They are ideal when fabric transparency makes seam visibility a concern.

Advanced Nahttypen for Strength and Durability

Some projects require stronger seams that can withstand tension and repeated use. These advanced nahttypen are designed for durability.

Flat-Felled Seam as a Durable Nahttypen Option

The flat-felled seam is among the strongest nahttypen available. It involves folding and stitching fabric edges so that no raw edges remain exposed. This seam is commonly used in denim garments, workwear, and sportswear.

Flat-felled seams are durable and resistant to fraying, making them ideal for garments subjected to heavy stress. Although they require more effort to construct, the result is a professional and long-lasting finish.

Reinforced Seam in Technical Nahttypen

Reinforced seams are specialized nahttypen designed to handle high-stress areas such as shoulders, crotches, and armholes. These seams often involve multiple rows of stitching for added strength.

They are commonly used in uniforms, outdoor clothing, and industrial textiles where reliability is essential. Reinforced seams enhance safety and extend garment life.

Decorative Nahttypen and Their Visual Appeal

Not all nahttypen are purely functional. Some are chosen specifically for their decorative qualities.

Decorative Seam in Creative Nahttypen

Decorative seams add visual interest to garments and accessories. These naht-typen may use contrasting thread, visible stitching patterns, or ornamental designs.

Commonly seen in fashion-forward clothing, decorative seams allow designers to highlight structure while enhancing style. They are often used in jackets, skirts, and accessories to create unique visual effects.

Topstitched Seam in Fashion Nahttypen

Topstitched seams are visible on the outside of garments and serve both functional and decorative purposes. This type of seam strengthens edges while adding a clean, professional look.

Topstitching is frequently used in jeans, collars, and pockets. Among modern naht-typen, it is popular for combining durability with design appeal.

Industrial Nahttypen in Textile Manufacturing

Large-scale textile production relies heavily on standardized naht-typen to ensure consistency and efficiency.

Overlocked Seam in Industrial Nahttypen

The overlocked seam, created using an overlock machine, trims and finishes fabric edges simultaneously. This seam prevents fraying and is widely used in mass-produced garments.

Overlocked seams are efficient, cost-effective, and suitable for knit and stretch fabrics. They are commonly found in t-shirts, activewear, and casual clothing.

Safety Seam as a Specialized Nahttypen

Safety seams combine a plain seam with an overlocked finish, offering both strength and edge protection. These naht-typen are commonly used in children’s clothing and workwear.

They provide additional security, making them ideal for garments that require extra durability without sacrificing comfort.

Choosing the Right Nahttypen for Your Project

Selecting appropriate naht-typen depends on fabric type, garment purpose, and desired finish. Lightweight fabrics benefit from enclosed seams, while heavy-duty textiles require reinforced or flat-felled seams.

Understanding these factors allows sewists and designers to create garments that balance aesthetics, comfort, and durability. Proper seam selection also reduces fabric waste and improves overall construction quality.

The Future of Nahttypen in Modern Sewing

As textile technology advances, naht-typen continue to evolve. Innovative stitching techniques and automated machinery are enhancing seam precision and efficiency. Sustainable fashion trends are also influencing seam choices, encouraging designs that extend garment lifespan.

From traditional hand-sewn methods to advanced industrial applications, naht-typen remain a fundamental aspect of sewing and textile production.

Conclusion

Naht-typen are more than just ways to join fabric; they are essential elements that define the quality, strength, and appearance of textiles. Whether used in simple home sewing or complex industrial manufacturing, the right seam type ensures reliable and attractive results.

By learning about different naht-typen and their applications, designers, tailors, and hobbyists can improve their skills and create garments that stand the test of time.